Product

Automated Weighing & Batching

With extensive experience in automated weighing and batching of materials from grams to Tons, Autosys can not only improve the quality and consistency of your end product but can also make major improvements in cycle times (process throughput time) and plant output capacity.

Sample list of equipment that we manufacture / source and integrate for your project:

- Weight indicators / Weighing scales

- Batching controllers, PLCs

- Control Panels

- Man Machine Interfaces, GUIs

- PC based control room software

- Formulation and Tank weighing

- Mono-rail weighing

- Liquid Weighing and Dosing

- Check Weighing

- Carousel Weighing

- Batch weighing as per IS S88 and IS S95 standards

Price of the Product

Category of the Product

Company website

5

products -

Autosys Engineering Private Limited

Our recommended products and services

-

-

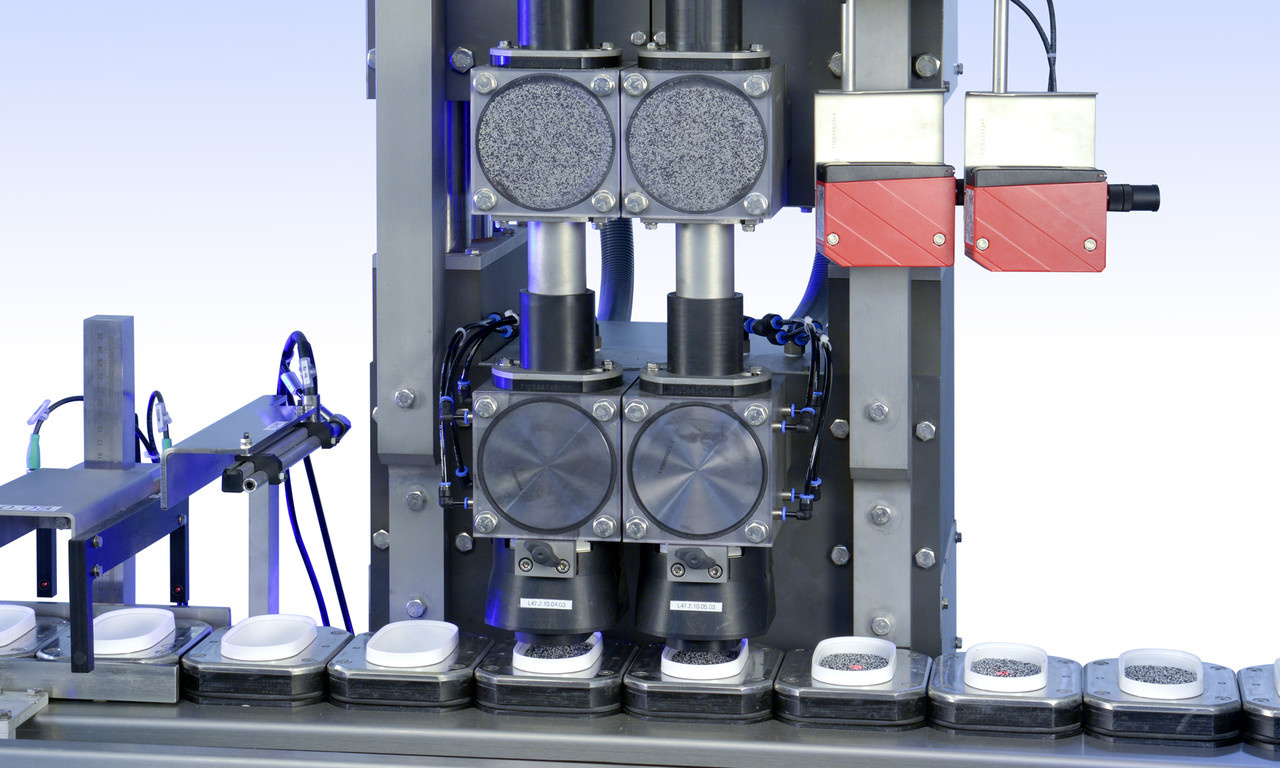

Dosing/Weighing - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

-

Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - Volumetric dosing with auger filler - High-precision positioning for constant filling weight/volume Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

-

Mixtures, sensitive granulates or powders require specific portioning solutions. For these applications, the function principle of OPTIMA VD portioning systems suits these requirements very well, featuring two pneumatically driven closing flaps alternately opening and closing, and portioning the product with highest precision. The benefits: The product is gently protected by the circular motion of the flaps.

-